UHV Hybrids. Mega Industries custom designs waveguide hybrids used in high power, UHV applications.

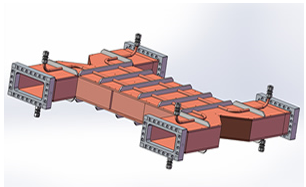

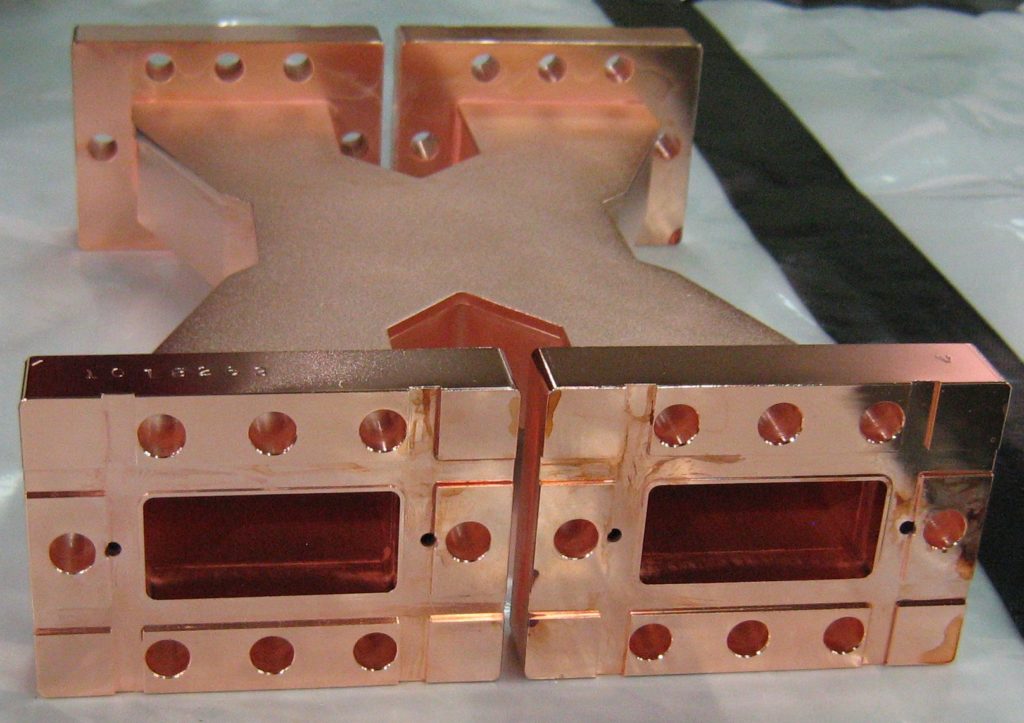

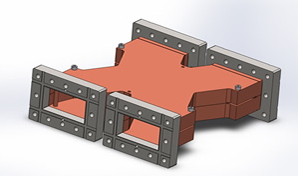

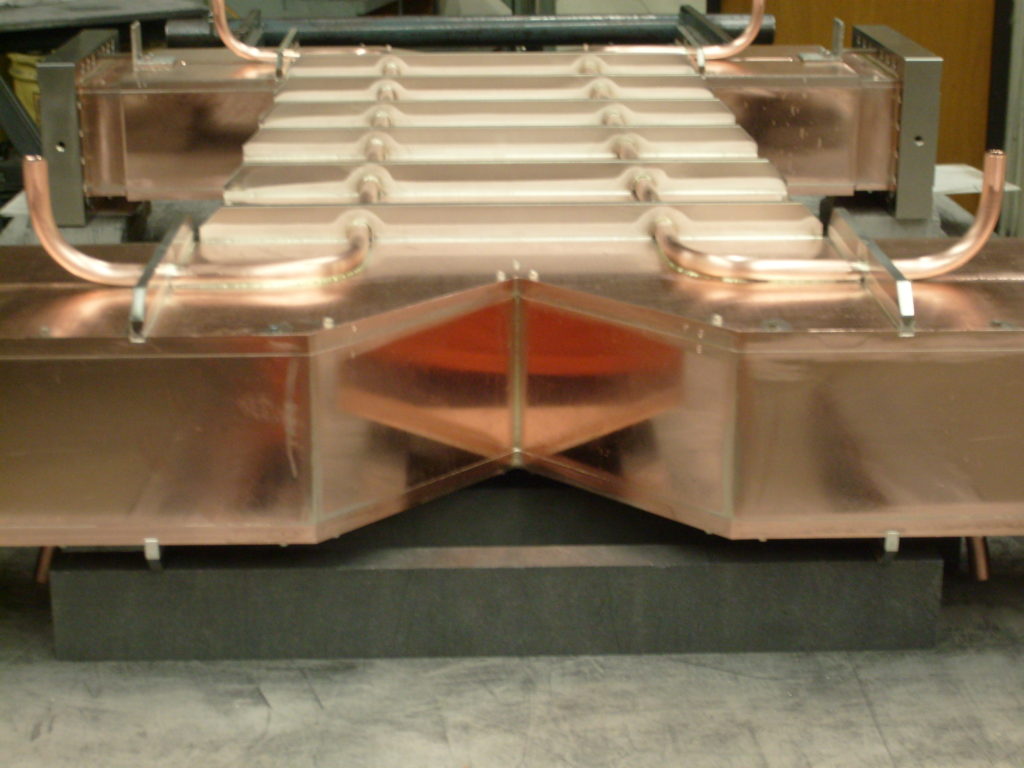

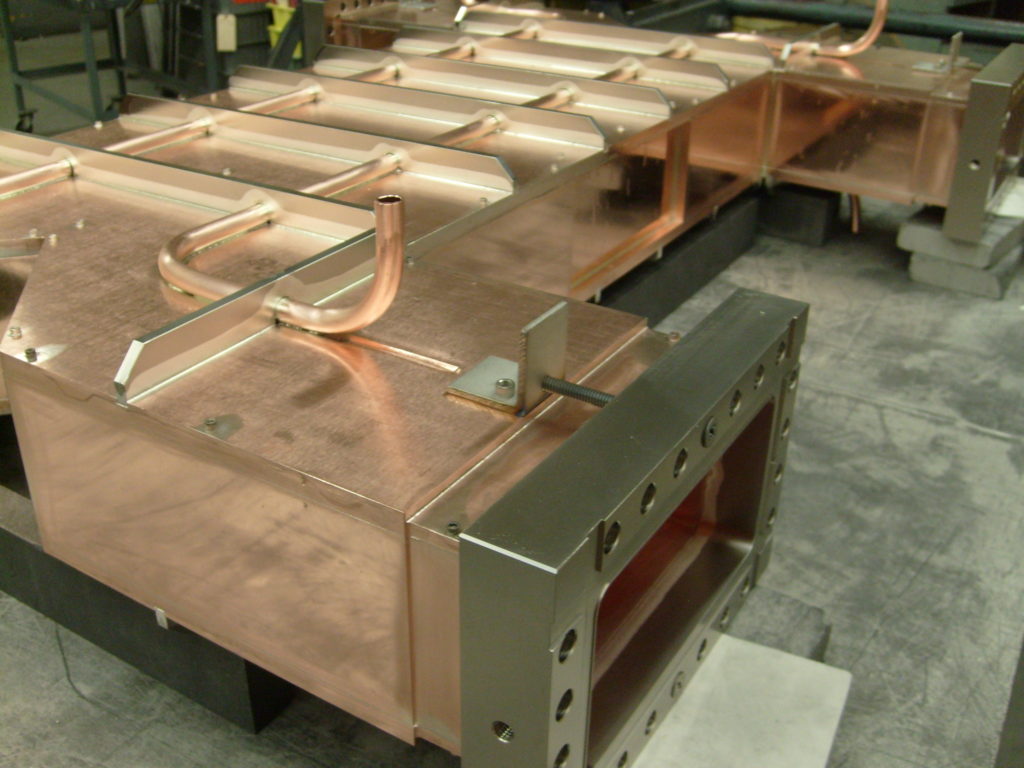

WR650 UHV 3db Hybrid with Phase Stabilization Cooling Ultra High Vacuum (UHV) Hybrid WR284 UHV 3dB Hybrid with DESY Flanges

Mega Industries produces an array of Ultra High Vacuum (UHV) compatible waveguide and coaxial components that are custom tailored to provide the high electrical performance in the Ultra High vacuum environment down to 1 x 10-12 Torr. That means all of these components are constructed using vacuum rated materials such as OFHC copper, non-magnetic stainless steel (304, 316L & 316LN), and ceramics such as alumina, sapphire and quartz. Our manufacturing process uses advanced vacuum-brazing techniques, and all components are cleaned, assembled and tested in our clean room facility.

Mega can test and verify many UHV Hybrid such as vacuum He leak rates down to 1.0 x 10-9 Torr l/s, and internal outgassing levels to 1.0 x 10-12 Torr l/s cm2 to deliver “UHV” clean components that can easily be integrated into your systems. Mega will perform bake out procedures and unique vacuum packaging protocols to ensure the components to be in a “vacuum ready” state.

The standard UHV level testing is:

1.0 x 10-6 Torr l/s for larger aluminum (WR650) parts or anything with elastomer seals.

1.0 x 10-9 Torr l/s for UHV (Standard).

Note: 1 Torr = 1.33mBar

Mega has designed and constructed many UHV Hybrids to date, each with unique characteristics and properties. Please examine the array of devices Mega’s vacuum experience has developed.

A trusted name in microwave technology since 1989, Mega Industries is a world leader in the manufacture of microwave transmission equipment. Please contact Mega Industries to discuss your specific UHV Hybrid needs.